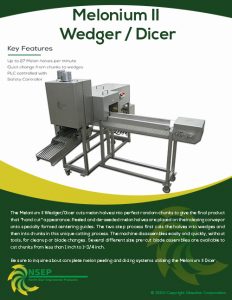

Melonium II Wedger / Dicer

Melonium Cutting System - Optimizes cut regularity / Maximizes yield.

Melonium Cutting System - Optimizes cut regularity / Maximizes yield.

The Melonium Dicer cuts melon halves into perfect random chunks to give the final product that "hand cut" appearance . Peeled and de-seeded melon halves are placed on the indexing conveyor onto specially formed centering guides.

The two step process first cuts the halves into wedges and then into chunks in this unique cutting process.

The machine disassembles easily and quickly, without tools, for cleanup or blade changes . Several different size pre-cut blade assemblies are available to cut chunks from less than 1 inch to 1-3/4 inch.

Be sure to inquire about complete melon peeling and dicing systems utilizing the Melonium II Dicer.

KEY FEATURES

- Wedges drop directly into treatment tank

- Radial pre-cutter provides optimal chunk size

- Aligns melon to reduce scrap

- Capacity - up to 27 melon halves per minute

- Quick release latch - for easy removal of radial blade rack

- PLC controlled

- Two-step shaker design to remove fines

- Quick change from chunks to wedges

- Easy to load and clean

- Simple blade changes

CUT SIZE OPTIONS

- With 6-blade pre-cutter - 1" x 1" x 3/4"

- With 8-blade pre-cutter - 1" x 3/4" to 1" x 5/8"

- 3/4" cube cut available

COMPATIBLE NSEP EQUIPMENT

- Trim Table

- Versa Peeler

SPECIFICATIONS

| Melonium II System | Specifications |

|---|---|

| Width | 84 Inches |

| Length | 81 Inches |

| Overall Height | 62 Inches |

| Load Height | 36 inches |

| Discharge Height | 23 Inches |

| Total Weight | 650 lbs. (approx.) |

| Electrical | 230 Volt / 3 phase |